Vibrational monitoring is one of the fastest ways to assess condition of a compressor turbine (without taking an enclosed charge case off). It makes the conversion of motion into data, which allows reliability engineers enough information to link together minor problems into bigger catastrophes. If you correctly clarify the vibration data, the geyser that provides condition is believable and a maintenance decision can be made on knowledgeable data and condition. Vibration also provides consistency of language for operations, maintenance, and engineering to actionability together.

Basics of Vibration Monitoring

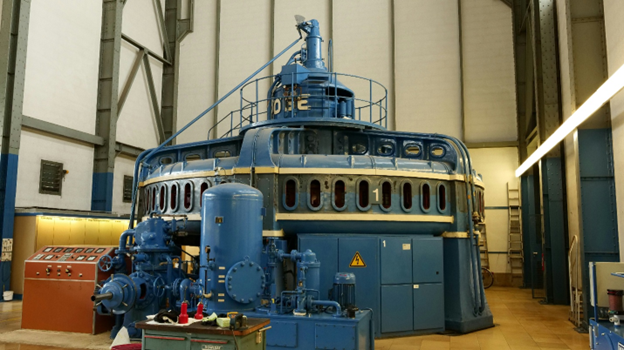

Vibration monitoring (see here for details) is measuring if and how much components move while in operation. In compressor turbines this signal will measure bearing, coupling, seals, and blade behavior. This is rotor dynamic behavior. As one specific condition monitoring methodology, it establishes a baseline condition from which to observe changes from normal.

- Running speed (1x) and harmonics (2x, 3x) allow you to correlate to common faults like imbalance and misalignment.

- Whether an issue is stable, increasing, or intermittent is because of trend that relates amplitude and phase.

- Time waveform and frequency spectra will identify impacts, rubs, and resonance shapes that one number may only require.

These indicators establish an early warning grid that can trend week over week.

Identifying Imbalance Early

Imbalance is the classic vibration fault. Tradition indicates that it presents itself from fouling, buildup on the rotor or small loss of rotor material. The strong signal to watch for is a single, dominant (and stable) 1x running-speed peak. Catching it early will avoid additional bearing load, heat generation, and seal wear which increases the risk of operations. Engineering teams will do trim or field balancing and then check the improvement through trending. When the imbalance returns, the team checks the alignment, coupling fit, and rotor cleanliness as part of a broader reliability strategy.

Two-plane balancing is generally the best for long, flexible rotors, and a single-plane calibration is indicated for short, stiff rotors. If there is a soft-foot or bent shaft, then the balancing results will fluctuate and should be corrected for the root cause first.

What Vibration Tells About Blades

Blades show themselves through the spectrum. Blade-pass frequency (BPF- https://www.sciencedirect.com/topics/engineering/blade-passing-frequency) is typically the number of blades multiplied by running speed. Even in steady state, if the signal shifts around the BPF, it likely indicates fouling, changes in blade tip clearance, or an incipient crack. Analysts usually check spectra from several vibration probes, combining the results and looking at the operating history to distinguish a blade from a rotor fault.

- Rising BPF peaks can indicate fouling or uneven tip clearance developing across several stages.

- Sidebands around the BPF suggest looseness, and or cracked blade altering the BPF frequency.

- A broad band of high-frequency energy can indicate light rubbing or surge events, which can be coincident with rub marks.

Findings are often coupled with non-destructive testing technique(s) to verify suspected damage during a planned outage. After cleaning or some light blending, it is advisable to record a fresh BPF for comparisons, and document the status and action.

Using Sensors for Data Collection

Good data starts from good sensors. Accelerometers record vibration at the casing; eddy-current proximity probes measure shaft displacement; a keyphasor reference ties vibration to shaft angle so the impact can be diagnosed; and provide a means of calculating phase. A good sensor has adequate sampling rates, anti-aliasing filtering of the signals, and synchronized channel rates will present clean, comparable data sets.

Many compressor turbine services now package the sensor, data acquisition, and analytics so reliability engineers can focus on observations, algorithms, and diagnosis. Integrated dashboards link the plant’s predictive maintenance program, connecting the alerts to alerts, work orders, and spare parts. Regular calibrating of sensors and bump tests is necessary to maintain trust in the numbers. Shielded cables and proper ground all help reduce electrical noise that can obscure real faults.

Reducing Unplanned Shutdowns

Unplanned trips usually trace back to unnoticed growth in vibration. A disciplined and quality program will reduce surprises by creating a combination of permanent monitoring, periodic route-based checks, and a quick follow up action when alarms are triggered. The benefit is less forced outages, allowing the crew to better plan operations, and higher availability of the rotating assets across the facilities.

- Assign alarm limits and danger bands based on the baseline from the reliability asset not by other common limits and perform trending both amplitude and phase.

- Align monitoring and routing to outages (and plan ahead): cleaning rotors, adjusting clearances, and get warranty approved targeted balance while there are often hurry accidents.

- After the fix is performed, accept that tests can be performed, or baselined again, and lessons learned to strengthen future diagnostics.

Looping the completed condition of alarm, diagnosis, fix, and updated baseline completes the diagnostic and event models, and makes every occurrence a little more confident to something that can be relied upon in the future.

Comments